The Role of AI in Data Center Filtration

AI is changing what data centers are, and in the process, it’s changing what filtration needs to be.

Most of the industry chatter around AI focuses on chips & software developments. But those of us in the filtration industry understand that when you double the power inside of a space, you’re also doubling the stress on every single piece of infrastructure that keeps the operation stable. Filtration is one of the first stress points that will have a massive impact on the cost of operations.

According to the International Energy Agency, global data center energy demand is expected to more than double by 2030 due to AI growth. Not only will more heat have to be cooled, but it will have to cooled faster, more efficiently, and in more constrained ways than before.

What AI Means for The Future of Filtration

As AI workloads increase, data centers will experience higher rack densities, tighter temperature tolerances, and more continuous operation. This fundamentally shifts the filtration conversation from protection to performance.

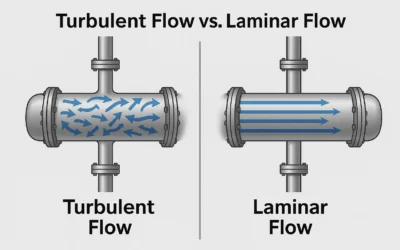

Every watt counts now. Filters that once seemed sufficient are becoming efficiency liabilities if they restrict airflow or raise pump pressure too much. The future of filtration lies in solutions that maintain cleanliness without sacrificing flow or energy efficiency—whether that’s through low-resistance media, smarter changeout strategies, or condition-based monitoring.

In short: filtration must evolve in parallel with AI. Not reactively, but proactively.

Air Filtration for AI Data Centers

Traditional air filtration in data centers has revolved around maintaining clean environments for servers, cooling coils, and heat exchangers. But as heat loads rise, the way we think about air changes.

Airflow rates will need to increase, but fan power can’t scale linearly—energy costs won’t allow it. That’s where low-pressure-drop, high-efficiency media come in. Filters must trap fine particles while letting air move freely, maintaining high cleanliness standards without driving up energy consumption.

Data centers located near cities or industrial areas face another growing issue: airborne corrosive gases. These gases, like sulfur dioxide and ozone, corrode metals and damage electronics over time. Expect to see more facilities incorporating gas-phase filtration systems—carbon or chemisorbent filters—to control corrosion and maintain long-term reliability.

In the near future, performance specs will likely reference both particle and gas filtration, and filter selection will become a measurable factor in a site’s Power Usage Effectiveness (PUE).

Liquid Cooling Systems

Every data center is comprised of both network switches and servers. As this hardware expands its capability due to the demands of AI growth, filtration solutions must become more efficient and scalable – and unfortunately, air filters are just not cutting it.

So what is the alternative to air filtration as AI requires more efficient cooling?

Liquid cooling systems have become the most efficient way to manage heat generated by network switches and servers. These liquid cooling systems must be treated and maintained regularly to ensure that the process liquid is properly operational.

Beyond the liquid cooling systems themselves, the liquid within the cooling systems must be exceptionally clean.

Even tiny particulates can clog narrow channels in cold plates, reduce heat transfer, and cause localized hot spots. To prevent this, data centers are starting to implement multi-stage liquid filtration—including fine inline strainers (often around 5–10 micrometers) and side-stream polishing systems that continuously clean the loop.

Filtration in these systems isn’t static; it’s monitored. Sensors track pressure drop, flow, and temperature differentials, giving operators real-time data on coolant quality and fouling before performance degrades.

As water-based cooling expands, chiller towers and make-up water systems will also demand more attention. Scale, biofilm, and corrosion control will depend on tighter water filtration and treatment programs.

To sum up – liquid filtration is quickly becoming the backbone of AI’s cooling infrastructure in data centers around the world.

Emergency Generator Fuel Filtration

Data centers depend on back up generators to keep critical processes online. As data center infrastructure evolves with newer & more advanced hardware, their will be a greater reliance on back-up power systems like emergency generators.

This significant dependency only further emphasizes the importance of ensuring that generator fuel is clean and ready to be used in the case of an unexpected outage. If a data center’s generator fuel is not clean when they need it most, potentially hundreds of thousands to millions of dollars worth of operational time could be lost.

Naturally, it is best practice to employ a preventative maintenance program that mitigates such disasters.

Routine diesel fuel polishing & tank cleaning services are essential for maintaining fuel quality at evolving critical facilities like AI Data Centers. These routines help ensure that diesel stored for long periods of time is not contaminated by condensation, rust, debris, and other particulate matter.

Precision Filtration Products: AI Data Center Filtration Solutions

AI is transforming not just how data centers compute, but how they breathe, cool, and sustain themselves. The rise of liquid cooling, the need for ultra-low-resistance air filtration, and the growing importance of gas-phase corrosion control all point to one truth: filtration has become a cornerstone of efficiency in the AI era.

For over 30 years, Precision Filtration Products (PFP) has built its reputation on helping industries protect the systems that keep their operations moving. As data centers evolve to meet the demands of AI, PFP continues to offer innovative solutions that welcome scalability.

We provide 24/7 on-site filtration services and maintain a large rental fleet of filtration equipment engineered for critical data-center applications—from high-efficiency air systems to liquid-cooling and water-treatment processes. Our goal is simple: to help facilities scale safely and efficiently as workloads grow more complex.

AI is changing everything about how data centers operate. PFP is here to make sure they run cleaner, longer, and smarter.

Looking to future proof your data center?

Give us a call or request a quote today to see how PFP can help your operation stay ahead of what’s next.