Bulk fuel contamination is a reality for any operation that stores or transfers high volumes of diesel, jet fuel, or gasoline. Tanks corrode. Water finds its way in. Additives breakdown. Microbes thrive in dark corners of storage tanks. Even when systems may appear clean, contamination silently degrades product quality and risks downstream damage.

This guide will provide a comprehensive overview of how bulk fuel contamination takes root – and why bulk fuel filtration is often the most direct, scalable, and cost-effective path to recovery.

What is Bulk Fuel Contamination?

Bulk fuel contamination refers to the degradation or pollution of stored or transferred fuel. It often results from environmental exposure, improper storage conditions, chemical instability, or microbial activity. While some effects are visible, many of the most damaging consequences occur on a microscopic or chemical level.

Types of contaminants commonly found in bulk fuel systems include:

- Water: from condensation, rainwater intrusion, or temperature cycling

- Microbial Growth: bacteria & fungi thrive in fuel/water interface

- Particulates: rust, scale, and environmental debris from tank/pipe corrosion

- Degraded Additives: fallout from older stabilizers, lubricants, or treatments

- Color Bodies & FAME: chemical residues or biodiesel blending components

- Surfactants: leftover chemical agents from previous treatments or blending

Any one of these contaminants can cause filter plugging, injector damage, combustion inefficiency, or equipment failure – often without a visible or obvious warning.

How Bulk Fuel Contamination Happens

Bulk fuel moves constantly. From refineries to terminals, then terminals to transport, then transport to storage tanks, and finally into equipment. Each transfer point is an opportunity for contamination at large scale. Over time, most fuel systems accumulate moisture, debris, and chemical residue.

Stagnant fuel allows water to separate out, collecting at the bottom of tanks where microbial colonies form and grow exponentially. These organisms produce acidic byproducts that attack tank surfaces, leading to further corrosion and sedimentation. Even in tightly managed environments, bulk contamination is a slow & cumulative process that builds until failure points emerge.

What Are the options for Handling Bulk Contamination?

When large-scale contamination is discovered in fuel storage or transit, the response window narrows very quickly. For operators, the priority is clear: get the fuel clean, reliable, and usable without disrupting the broader system of operations. But the path to that outcome can vary depending on infrastructure, timing, and even internal capabilities.

At a high level, there are three general categories of response to bulk fuel contamination:

- Downgrading the fuel for less critical use

- Sending it offsite for chemical reprocessing or disposal

- Treating it on-site with high-flow bulk fuel filtration systems

Each of these options carries different implications for cost, timeline, and operational integrity. What may seem like a quick fix in theory often introduces hidden inefficiencies when put into practice. And for high-volume fuel systems — particularly those supporting aviation, power generation, or backup critical infrastructure — time is rarely on your side.

The Problem with Downgrading & Reprocessing Fuel

Many operators default to two common responses: either downgrade the fuel for lower-value applications or send it offsite for reprocessing. While both may seem viable in theory, and can be practical approaches in certain cases, these two responses often end up creating more problems than they solve.

Downgrading typically involves reassigning off-spec product to less critical equipment or blending it into lower-grade reserves. This might preserve some of the fuel’s value, but it doesn’t recover its intended purpose – and it creates downstream inconsistency. Over time, you’re left with a patchwork of degraded fuel quality across different systems, none of which meet the original performance requirements. And even worse, the root cause – tank contamination, water ingress, microbial growth, pipe scale, etc. – is still present and causing problems. So even if new fuel is introduced, the cycle of degradation simply continues.

Offsite reprocessing, on the other hand, introduces a range of logistical and economic challenges. First, the contaminated fuel must be transferred out of it’s storage tank and into transport-safe containers. This alone can take hours or days depending on the volume. Then comes freight coordination, turnaround time at the reprocessing facility, and final transport back to site. By the time product is recovered (if it’s recovered at all), you’ve spent far more on labor, downtime, and shipping than the fuel was originally worth – all while your system remains idle or operating below capacity.

In both cases, operators are spending more money to delay the problem rather than solve it. Neither option addresses system health, and neither guarantees that future deliveries won’t be contaminated the same way. In most critical industries, these risks cannot be taken.

Large-scale flushing operation conducted by PFP to address bulk fuel contamination.

Why Bulk Fuel Filtration is Often the Best Solution

Rather than accepting fuel loss or absorbing the logistical cost of offsite handling, on-site bulk fuel filtration offers a proactive, field-based solution that restores product & system integrity without disrupting operations. With the right filtration systems in place, tens of thousands of gallons can be processed on-site quickly, safely, and within strict fuel specifications. The infrastructure itself, meaning the tanks, lines, and other equipment, is remediated in parallel.

Unlike reprocessing or downgrading, bulk fuel filtration solutions deliver measurable results immediately. Operators can resume operations with confidence in a fraction of the time required by traditional remediation routes.

PFP’s Bulk Fuel Filtration Solutions: Rental Equipment & On-Site Services

At the core of any successful fuel remediation program is equipment & personnel that can actually handle the scale, flow rate, and contaminant load present in industrial fuel systems. That’s where Precision Filtration Products (PFP) stands apart.

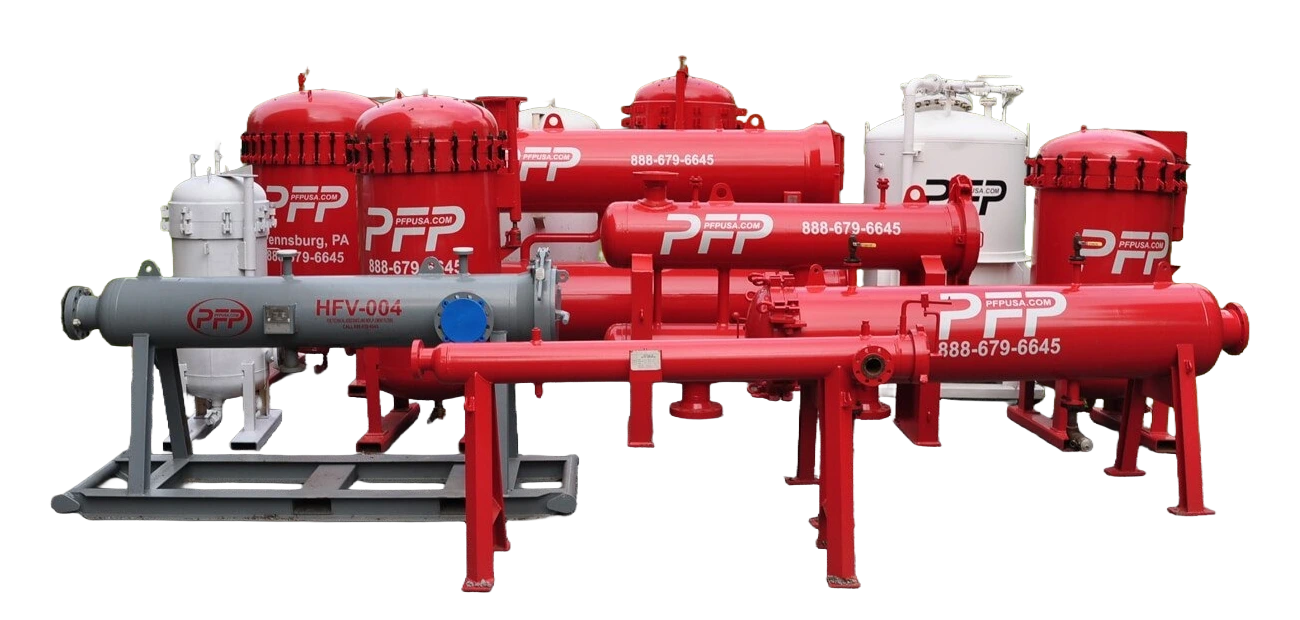

We operate one of the largest rental fleets of industrial filtration equipment, built specifically to address bulk fuel contamination. Our fleet offers a variety of equipment, including:

- High-Flow Filter Vessels: Industrial grade filter housings (bag or cartridge) built for large-scale particulate removal and fuel polishing applications.

- Coalescer-Separators: Specialized systems that efficiently remove free water and solids from fuel.

- Vacuum Dehydrators: Designed to extract free, emulsified, and dissolved water from fuel and oil.

- Clay Treater Vessels: Media-based systems that remove surfactants, additives, color bodies, and other dissolved contaminants through absorption. Often used in jet fuel remediation and specialty applications.

- Carbon Vessels: Removes dissolved hydrocarbons, discoloration, and residual chemical byproducts via high-adsorption carbon media.

In addition to our wide variety of bulk fuel filtration equipment & systems, we offer on-site bulk fuel filtration services that are designed to address large-scale contamination of all kinds. Our field technicians can setup, operate, and breakdown bulk filtration systems directly on-site at your facility, quickly restoring product quality and system compliance.

We provide not only the equipment and personnel, but also detailed documentation and reporting of the contaminant levels present in your system — before, during, and after filtration. This includes ISO cleanliness verification, water content analysis, particulate load tracking, and field observations that help prevent recurrence.

Looking for reliable bulk fuel filtration solutions?

Give us a call or request a quote today to see how PFP can help your operation stay ahead of bulk fuel contamination.