Moisture is by far one of the most common and damaging contaminants found in hydraulic systems. It often goes unnoticed until its presence inevitably causes performance issues, equipment damage, and fluid degradation.

This blog outlines how moisture enters hydraulic systems, how it affects performance, and which remediation strategies are most effective for removing water from hydraulic oil.

Common Sources of Moisture Contamination

Hydraulic systems are not immune to water intrusion. Moisture can enter the system through several pathways:

- Condensation

- Occurs when warm, humid air cools inside the reservoir

- Most common in unconditioned environments with wide temperature swings

- Seal Failure

- Worn or damaged seals allow ambient moisture into the system

- Frequent issue with outdoor or mobile equipment

- Fluid Handling Practices

- Contaminted “new” oil or open containers left in humid environments.

- Use of unsealed transfer hoses or funnels

- Maintenance

- High-Pressure cleaning or water exposure during maintenance

- Breathers and vents left uncovered

Types of Water in Oil

Understanding the form of water present is important for selecting the right removal method.

| Type | Description | Visibility |

|---|---|---|

| Dissolved Water | Water molecules absorbed in the oil | Not visible |

| Emulsified Water | Water suspended in fine droplets | Appears hazy or milky |

| Free Water | Water separating and pooling | Visible at the bottom |

Standard filtration may remove free water, but removing dissolved and emulsified water requires specialized filtration & dehydration equipment.

Negative Effects of Moisture in Hydraulic Oil

Water contamination impacts both the fluid and the components it comes in contact with. Key issues include:

- Corrosion: Internal rust on valves, pumps, & actuators

- Additive Depletion: Reaction with anti-wear and anti-oxidant additives

- Varnish & Sludge Formation: Accelerated oxidation due to water presence

- Seal Damage: Swelling or degradation of elastomers

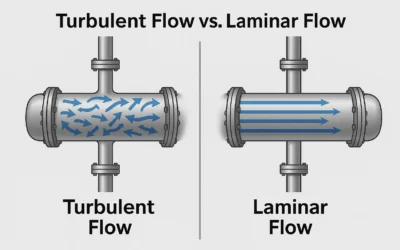

- Pump Cavitation: Micro-pitting from water vapor collapse under pressure

- Filter Plugging: Reduced efficiency and premature saturation

Water contamination in hydraulic oil results in both direct and indirect costs. Direct impacts include increased component wear, frequent filter changes, and early oil replacement. Indirect impacts may include unplanned downtime, loss of production efficiency, and extended troubleshooting time when failure root causes are unclear.

Addressing water contamination early prevents cumulative damage, reduces long-term maintenance costs, and improve overall equipment reliability.

Signs of Water Contamination

Water contamination may not always be visually obvious, especially if the water is dissolved or emulsified. However, there are several operational and visual indicators that suggest the presence of moisture in the system.

Indicators of moisture in hydraulic oil may include:

- Cloud or milky oil appearance

- Decreased system performance or inconsistent motion

- Reduced filter life or frequent clogs

- Presence of rust in drained fluid or components

- Elevated water content on lab analysis (measured in ppm)

Moisture Removal Methods

Effectively removing moisture from hydraulic oil depends on the form and volume of water present. Below are the primary methods used in industrial settings, along with when and how they are applied.

1. Vacuum Dehydration Units

Vacuum dehydration is the most effecive method for removing all three forms of water: dissolved, emulsified, and free.

These systems operate by heating the oil to a safe temperature and then exposing it to a vacuum, which lowers the boiling point of water and evaporates it without damaging the fluid.

Vacuum dehydrators are ideal for:

- Large oil reservoirs (500+ gallons)

- Critical systems where water must be reduced below 100 ppm

- Emergency water ingress events after flooding, washdowns, or system failures

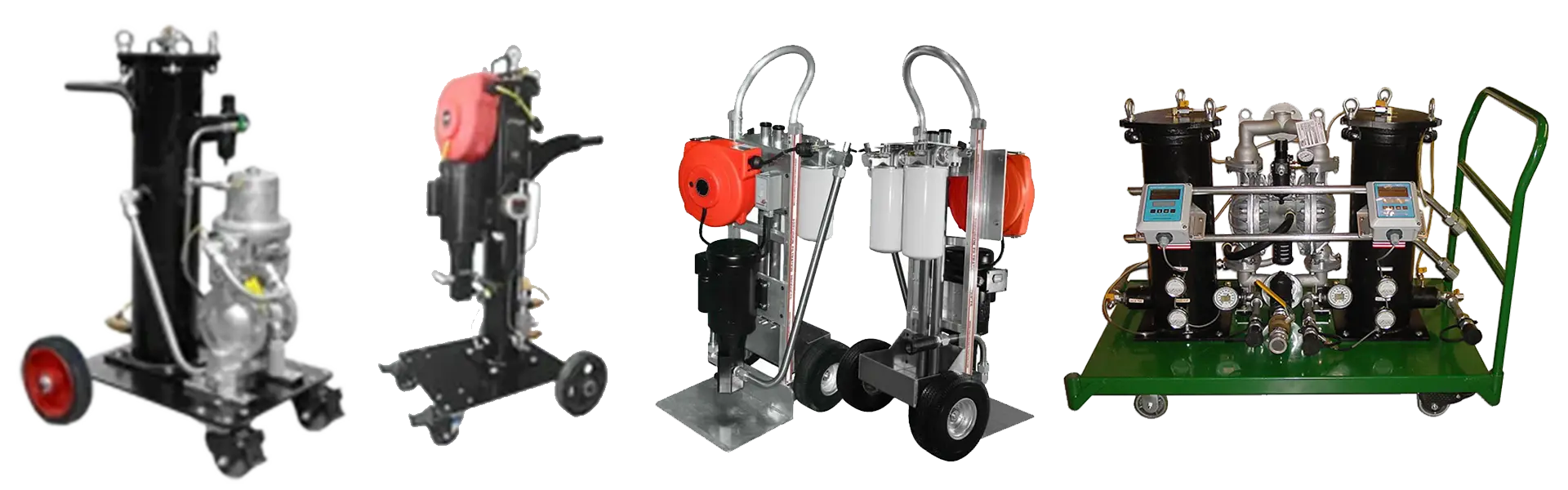

PFP offers vacuum dehydrator rentals that include technical guidance, quick-connect fittings, and optional on-site setup support. These units are designed for temporary use during system restoration, shutdowns, or maintenance.

2. Filter Carts with Water-Absorbing Elements

For smaller systems or routine maintenance, filter carts equipped with water removal media provide an efficient solution. These carts use disposable elements designed to absorb free and emulsified water from the fluid, in addition to capturing solid contaminants.

Water-absorbing filter carts are used to:

- Polish new oil before it’s added to a system

- Maintain cleanliness and dryness during standard operation

- Top off reservoirs while removing incidental moisture

Filter carts are especially useful for mobile equipment, small presses, or molding machines where a full dehydration unit would be overkill. PFP’s rental fleet includes filter carts with both particulate and water removal capability, sized for various flow rates.

How PFP Helps Address Moisture in Hydraulic Systems

For over 30 years, we have been providing the equipment, services, and technical support needed to effectively remove moisture from hydraulic systems.

Whether you’re responding to an active water contamination issue or planning a preventative maintenance routine, we offer vacuum dehydrator rentals, mobile filter carts, and on-site fluid purification services.

Looking for solutions?

If you’re looking for support on a project that involves moisture content in hydraulic oil or systems, contact us today to discuss your project requirements with one of our expert filtration specialists!