High Velocity

Oil Flushing

Services

On-site oil flushing services including high velocity oil flushing and reclamation services for industrial lubrication and hydraulic systems. – anywhere in the U.S.

Comprehensive Oil Flushing Services for Industrial Systems

Precision Filtration Products performs on-site oil flushing services to remove harmful contaminants like rust, scale, and particulate matter from industrial oil and fuel systems using turbulent flow.

Our high-velocity (high-flow) oil flushing services create turbulent flow, achieving a Reynolds Number greater than 4,000. This process efficiently removes all harmful contaminants, ensuring that your piping meets or surpasses the strict cleanliness standards set by top OEMs. Our technicians are rapidly dispatched to your facility with the knowledge required to service your equipment and ensure that you hit your target ISO cleanliness codes.

- Rapid, emergency response time

- Exceed OEM cleanliness standards

- 24/7 on-site support

- Turn-key services & equipment

- Realtime cleanliness reporting

Benefits of High Velocity Oil Flushing Services

Our Oil Flushing Services are designed to improve reliability at every level of your operation. By removing contamination that accelerates wear and disrupts performance, PFP helps reduce lubrication expenses, extend component life, and prevent unplanned downtime — ultimately strengthening your bottom line.

Improve Reliability

Our Oil Flushing Services remove varnish, sludge, and debris that cause wear and inefficiency — restoring smooth, consistent performance across your entire system.

Reduce Downtime

By eliminating contamination that leads to premature failure, PFP helps you reduce downtime, prevent costly outages, and keep production running continuously.

Minimize Maintenance

Cleaner systems require less maintenance, fewer oil changes, and reduced part replacement — cutting long-term operating costs and maximizing ROI.

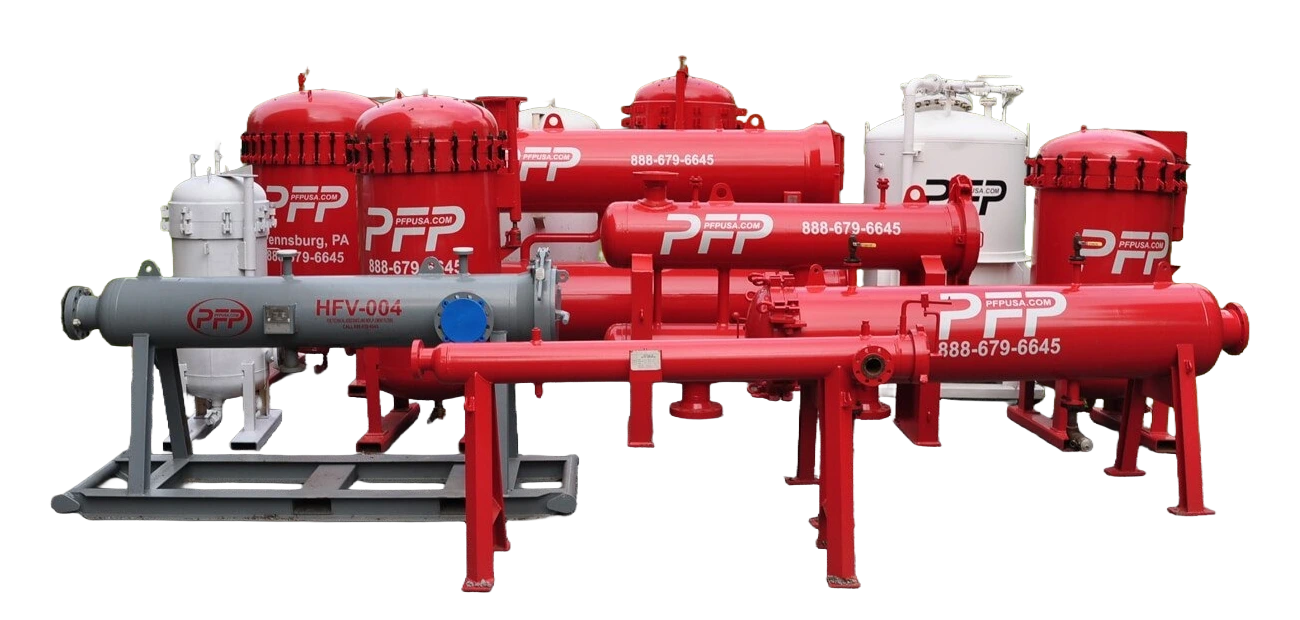

Industry-Leading Oil Flushing Systems & Equipment Fleet

Precision Filtration Products supports all High Velocity Oil Flushing Services with an extensive fleet of high-performance filtration and flushing systems — designed specifically to handle flows from 1 GPM to over 6,000 GPM. From compact filter carts to large-scale flushing skids, every unit is maintained to OEM standards and engineered to achieve target cleanliness in record time. Our oil flushing systems allow us to perform full high-flow oil flushes and fluid reclamation in a fraction of the time required by traditional setups, ensuring maximum uptime and verified ISO cleanliness results.

Our oil flushing filtration systems can achieve an ISO oil cleanliness level of 14/12/9 within minutes.

How Our Oil Flushing Services Work

Every Oil Flushing Service performed by Precision Filtration Products follows a proven, engineered process designed to achieve target cleanliness levels safely, efficiently, and with full traceability. We customize each flush based on system design, fluid type, and contamination level to guarantee a complete cleaning.

- System Assessment & Planning: We evaluate your system, identify restrictions, and determine optimal connection points for effective flushing.

- Setup & Configuration: Our team installs temporary hoses, manifolds, and filtration loops to achieve uniform flow and turbulence.

- High-Velocity Flushing: We generate turbulent flow (Reynolds Number > 4,000) to life and remove debris & contaminants.

- Oil Reclamation & Conditioning: Used oil is filtered, dehydrated, and restored to like-new quality on-site.

- Cleanliness Verification: ISO particle counts are monitored in real time until your system meets or exceeds OEM standards.

- Final Reporting: Each project concludes with a detailed report documenting flow data, ISO results, and recommendations.

On-Site Fluid Analysis

As part of our high-flow oil flushing services, we provide on-site diagnostics where we verify that your system is clean. After a full oil analysis, you will receive a formal report documenting the results.

On-Site Personnel Training

If you choose to perform the flushing with your in-house personnel, we offer on-site training as well as the rental filtration equipment required to meet your specific requirements.

Frequently Asked Questions

What is high velocity oil flushing?

High velocity oil flushing is a process used to clean lubrication and hydraulic systems by circulating fluid at high Reynolds numbers (typically >4000) to induce turbulent flow. This turbulence removes built-up contaminants like sludge, varnish, and debris from pipe walls and equipment internals. It’s commonly used before system startup or after major repairs in critical systems such as turbines, compressors, and gearboxes.

Why types of systems can be flushed?

We flush a wide range of systems including turbine lube oil systems, hydraulic circuits, gearboxes, compressors, diesel engine skids, and more. Whether it’s power generation or industrial manufacturing, we tailor the flushing method to your equipment.

How long does the oil flushing process take?

The duration of the flush depends on system size and contamination level. Smaller systems may take a few hours, while large turbine systems may require 1–3 days. We assess and scope timelines during the planning phase and can work around your schedule.