DPF Cleaning & Restoration Services

Restore Diesel Particulate Filters to OEM Performance – fast, reliable, and cost-effective.

AFFORDABLE DPF CLEANING SERVICES

Don’t replace your DPF. Let us clean it.

Replacing a diesel particulate filter is one of the most expensive repairs a fleet or equipment operation can face.

A new DPF can be a significant cost depending on the make, model, and equipment type. For municipal fleets and heavy equipment, replacement costs often climb much higher. But in most cases, you don’t need a new DPF. You just need a trusted partner who can restore your filter to like-new condition.

Why Choose PFP?

Save Thousands

Restoration to Factory Specs

Extend Equipment Life

Reduce Fleet Downtime

Lower Frequency of Regen

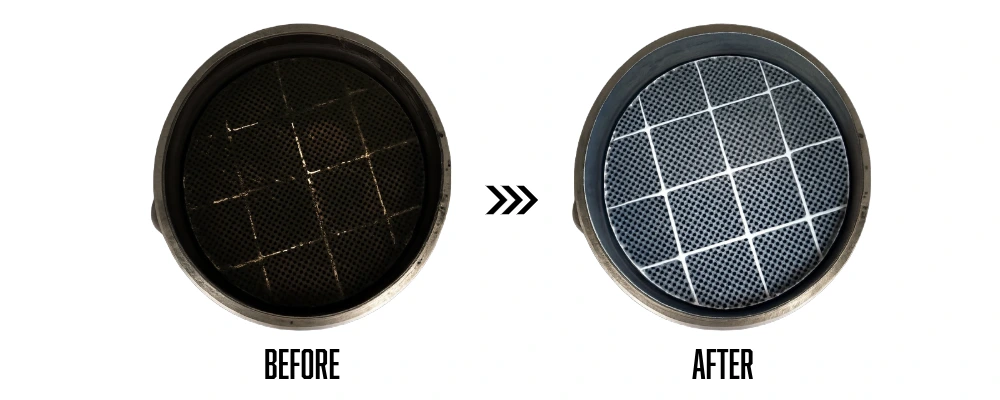

Our Cleaning Process

STEP 1: Inspection

We evaluate your DPF’s condition using visual inspection and flow testing to identify soot loading, restriction levels, and any potential structural issues.

STEP 2: Cleaning

Your filter undergoes a multi-stage cleaning cycle including heat, air, and chemical/water to eliminate soot and compacted ash to restore OEM-level flow performance.

STEP 3: Verification

Every DPF is re-tested after cleaning to verify proper airflow, confirm restoration results, and ensure it’s ready for immediate installation.

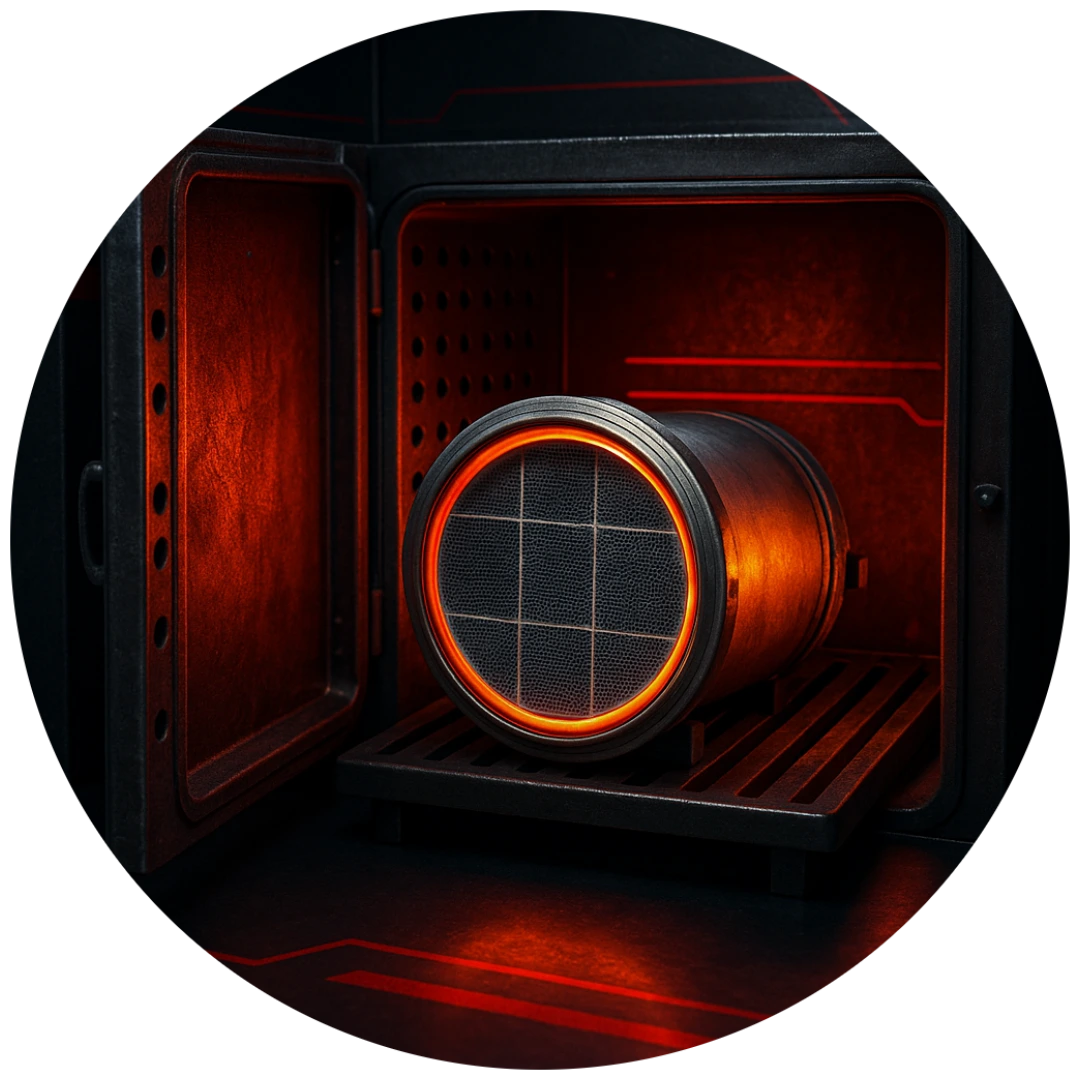

INDUSTRY-LEADING DPF CLEANING TECHNOLOGY

Ultrasonic Chemical Bath Cleaning

PFP’s Ultrasonic Chemical Bath is the most advanced and effective way to restore a diesel particulate filter. Unlike air-knifing or heat-only cleaning, ultrasonic cleaning reaches every cell of the filter, fully removing soot, ash, fuel contamination, and coolant deep inside the substrate. This process restores OEM-level performance and delivers measurable real-world savings for fleets and equipment operators.

- Restores 95-98% of original flow rate

- Improves mileage by up to 3% due to reduced backpressure

- Removes coolant and fuel contamination

- Rapid turnaround time to minimize downtime

FAQs

Why do I need to professionally clean my DPF instead of relying on regeneration alone?

Regeneration only burns off combustible soot. Over time, non-combustible ash, oil residue, fuel additives, and metal particulates accumulate inside the DPF and permanently reduce available filter volume. Professional cleaning removes these contaminants, restores exhaust flow, and prevents escalating backpressure that can lead to derates, shutdowns, or engine damage.

What industries commonly require DPF cleaning and restoration services?

DPF cleaning is most commonly required in industries that operate diesel-powered equipment under heavy load or frequent idle conditions, including transportation fleets, construction, mining, power generation, agriculture, material handling, and industrial manufacturing. Any operation running Tier 4 Final or emissions-controlled diesel engines can benefit from routine DPF maintenance.

Why is ultrasonic DPF cleaning more effective than air blasting or thermal methods alone?

Ultrasonic cleaning uses high-frequency sound waves in a liquid bath to dislodge compacted ash and fine particulates embedded deep within the DPF substrate. This allows contaminants to be removed evenly across all channels without damaging the filter media, making it especially effective for restoring airflow in heavily loaded or unevenly plugged filters.

How does professional DPF cleaning compare to full DPF replacement in terms of cost?

DPF replacement is significantly more expensive because it involves the cost of a new filter assembly, extended downtime, and potential recalibration or relearning procedures. Professional cleaning restores performance at a fraction of the cost while extending the usable life of the existing filter, making it a far more economical maintenance strategy in most cases.

Can DPF cleaning help reduce unplanned downtime and maintenance disruptions?

Yes. Routine DPF cleaning helps prevent unexpected derates, fault codes, and forced shutdowns caused by excessive exhaust restriction. By restoring airflow and stabilizing aftertreatment performance, cleaning supports predictable maintenance intervals and reduces the likelihood of emergency service events.

How do I know if my DPF is a good candidate for cleaning instead of replacement?

A DPF is typically a good candidate for cleaning if restriction is caused by ash or particulate buildup rather than severe structural damage. Professional inspection and differential pressure testing can determine whether the filter can be effectively restored or if replacement is the more reliable long-term option.