Aviation Fuel Filtration Services

30+ years of trusted aviation fuel filtration for airports, FBO’s, and military fueling operations.

Restore Aviation Fuel. On-Site & In-Spec.

Precision Filtration Products (PFP) provides nationwide, on-site aviation fuel filtration services and products to help FBOs, airports, and commercial fuel farms meet critical fuel quality standards. At any stage of filtration, our team of experts can rapidly remove contaminants from Jet A, Jet A-1, AvGas, and JP-8 fuel.

We offer quick-deployment options for emergency situations, with crews & equipment reaching customer sites in as little as 24 hours.

Aviation Fuel Compliance Made Easy

PFP has the equipment and expertise necessary to ensure that your Jet A, Jet A-1, JP-8, or AvGas is clean, dry, and ready for use.

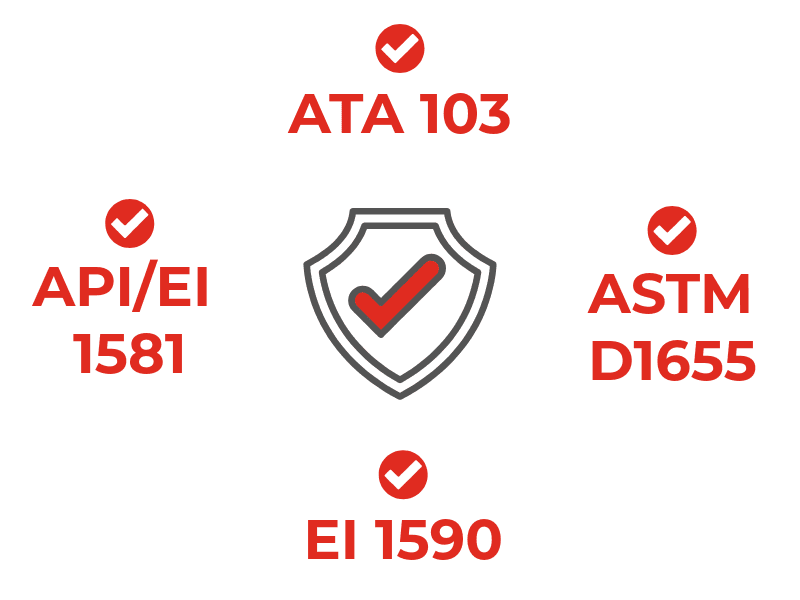

Our services and equipment support compliance with the following specifications:

- ATA 103 airport fueling guidelines (Airlines for America)

- ASTM D1655 aviation fuel standards (American Society for Testing and Materials)

- API/EI 1581 coalescer-separator performance (American Petroleum Institute & Energy Institute)

- EI 1590 particulate removal guidelines (Energy Institute)

We handle every part of the filtration process — setup, operation, fuel sampling, and teardown — so your team can stay focused on operations. Our trained crews arrive on-site with everything needed to restore fuel quality and support your compliance requirements without delay.

You get full service, zero stress, and guaranteed results.

Turnkey Filtration. Trusted Results.

Our team restores fuel quality with precision — delivering clean, spec-grade results on-site, backed by trusted equipment and decades of aviation fuel filtration experience. When performance matters, we make sure your fuel delivers.

Ready to get started? Contact us today to discuss your application and get a filtration solution tailored to your operation.

FAQ’s

What fuel quality issues most commonly cause aircraft fueling problems or delays?

The most common issues include free or entrained water, particulate contamination, microbial growth, and fuel degradation from long storage periods. Even trace contamination can trigger failed fuel quality tests, grounded aircraft, or rejected fuel deliveries, making proactive filtration and monitoring essential for uninterrupted operations.

How does water contamination enter aviation fuel systems?

Water can enter aviation fuel through condensation in storage tanks, temperature fluctuations, leaky seals, fuel transfers, or contaminated deliveries. Once present, water increases the risk of microbial growth, corrosion, filter plugging, and icing at altitude, all of which pose serious safety and compliance concerns.

When should aviation fuel filtration be performed instead of replacing fuel?

Fuel filtration is often preferred when contamination is detected early and fuel chemistry remains within specification. Filtration removes water and particulates while preserving usable fuel, reducing disposal costs and downtime. Replacement is typically reserved for severely degraded or chemically compromised fuel that cannot be restored through filtration alone.

Can aviation fuel filtration be performed while fueling operations remain active?

In many cases, yes. Filtration can be performed in parallel with normal operations depending on system configuration, contamination severity, and safety requirements. Each situation is evaluated to ensure compliance with aviation standards while minimizing disruption to fueling schedules and aircraft availability.

How does aviation fuel filtration support regulatory compliance and audit readiness?

Routine filtration, testing, and documentation help demonstrate adherence to aviation fuel quality standards and best practices. Maintaining clean fuel systems reduces the likelihood of failed inspections, rejected fuel loads, and compliance issues during audits or regulatory reviews.

What risks are associated with delaying aviation fuel filtration services?

Delaying filtration increases the risk of fuel system contamination spreading throughout storage tanks, hydrant systems, and aircraft. This can lead to grounded flights, emergency maintenance, reputational damage, and costly corrective actions. Proactive filtration helps prevent small issues from escalating into operational or safety incidents.