separator cartridges

Cleanable, Reusable Separator Cartridges

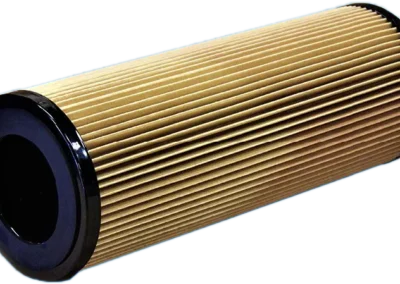

Precision Filtration Products (PFP) Pleated, Synthetic and Teflon separator cartridges are cleanable and reusable separator cartridges of the highest quality in a variety of dimensional configurations. Teflon® coated screen is wrapped around a treated, perforated metal shell, lock-seam folded and secured by metal clips, then adhesive bonded to gasketed metal end caps. The screen is Teflon® coated for more effective water repelling characteristics assuring long, trouble-free service.

Advanced Media, Superior Filtration

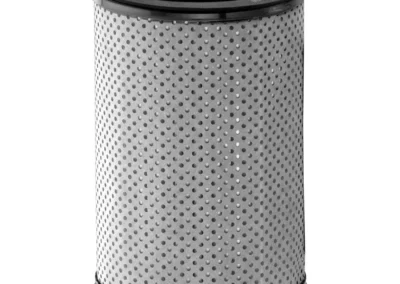

PFP’s synthetic separator cartridges feature a specially developed hydrophobic synthetic media which offers all the permanent features of Teflon® screen, with the ability to handle higher flow rates. Synthetic mesh is wrapped around a treated, perforated metal shell, then adhesive-bonded to gasketed metal end caps. The synthetic mesh is designed for more effective water repelling characteristics, assuring long, trouble-free service. The filter separator cartridges pair with the Coalescing Filter Elements are ideal for water removal in Bulk Fuel and Aviation applications. Check out our Coalescer Separator Filter Vessels in our Rental Fleet.

Both types of our filter separator cartridges have a distinctive PFP technology which provides balanced flow of product (radially inward) throughout the cartridge. All metal components are treated to resist corrosion. Maximum recommended operating temperature is 240°F. For compatibility in extreme operating conditions, other gasket, adhesive and metal materials are available.

Have questions? Reach out to us – we’re here to help!

STANDARD DESIGN FEATURES

- Cleanable and reusable

- Superior water barrier

- Recommended maximum operating temperature: 240°F

- pH range from 5 to 9

- Designed for balanced flow through cartridge

- Flow direction: Outside to inside

MATERIALS

- Synthetic mesh OR Teflon® coated screen

- Treated metal components for corrosion protection

- Buna-N gaskets

- Other gasket, adhesive and metal materials are available on request

FAQs

How do separator cartridges differ from standard particulate filter cartridges?

Separator cartridges are designed to remove entrained water from fuel or oil streams, not just solid particles. They promote coalescence and separation rather than simple particulate capture.

What fluids are these separator cartridges compatible with?

These separator cartridges are commonly used in aviation fuel, bulk fuel, diesel, and other hydrocarbon-based fluids. Compatibility with specific fuels or additives can be confirmed prior to selection.

How do I determine the correct separator cartridge for my vessel or housing?

Selection is based on vessel model, cartridge dimensions, flow rate, and application requirements. PFP can cross-reference existing cartridges or assist with sizing for new installations.

What operating conditions should be considered when selecting a separator cartridge?

Key considerations include operating temperature, pressure, flow rate, fluid type, and water content. These factors help determine media type and construction materials for reliable performance.

Are these separator cartridges suitable for bulk fuel and aviation applications?

Yes. These separator cartridges are commonly used in bulk fuel handling and aviation fuel filtration, where effective water removal and consistent fuel quality are critical.

What causes separator cartridges to lose effectiveness over time?

Separator cartridges can lose effectiveness due to excessive water loading, particulate fouling, improper cleaning methods, or operation outside recommended flow and temperature limits. Monitoring differential pressure and water removal performance helps determine when replacement is required.

Want the most up to date information from PFP?

Sign up for our E-mail newsletter!

Want the most up to date information from PFP?

Sign up for our E-mail newsletter!