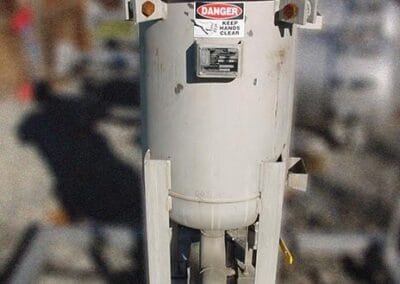

Pre-Filter Particulate Vessels

Vertical & Horizontal Vessels

PFPUSA has for sale a large inventory of both Vertical and Horizontal Pre-Filter Vessels. (We also offer Pre-Filter Vessels for rent as well.) Pre-Filter Vessels are designed to remove particulate contamination, such as, dirty, rust, sediment, pipe scale, sand and metal from the fuel stream. They are typically located upstream or in front of Clay Treaters and Coalescer Separators. This is designed to protect and prolong the life of the more expensive filter cartridges, which is especially important if you are considering such a purchase.

Our Pre-Filter Vessels are available for purchase in flow rates up to 25,000 GPM and in various pressure ratings.

PFPUSA offers both cartridge and bag style pre-filter vessels currently for sale.

Have questions? Reach out to us – we’re here to help!

Materials of Construction

- Carbon Steel

- Stainless Steel

Accessories & On-Site Support

We can supply you with the temporary Cargo Hose, Gate Valves, Tees, Elbows, Pump, Portable Containment, and many more to provide you a complete turnkey set up. We have service crews available to set up, monitor, and breakdown the temporary systems as well.

- Vertical & horizontal configurations available

- Designed to filter solids

- Easy service and reduced maintenance costs

- EI 1596 Design & Construction

- Built to ASME Code, Section VIII, stamped and certified or “CE” marked

- Standard Design for 150 PSI (10.5 kg/cm2) @ 250°F (121°C) – higher pressure and temperature ratings available upon request

- Water

- Diesel Fuel

- Gasoline

- Jet Fuel

- Lube Oil

- Hydrocarbons

- Automatic air eliminator

- Automatic air eliminator check valve

- Differential pressure gauge

- Pressure relief valve

- Sampling probe

- Manual drain valve

Frequently Asked Questions

Can pre-filter particulate vessels be used as a standalone filtration step?

Yes, but they’re most effective when used as the first stage in a multi-step system. As a standalone, they remove bulk solids, but they don’t achieve fine clarity or polishing quality on their own.

Do pre-filter vessels require frequent basket or element changes?

Changeout frequency depends on particulate load, flow rate, and fluid condition. High-contamination projects (tank cleaning, construction sites, transfers from old tanks) require more frequent monitoring, while routine operations need far fewer interventions.

What industries most commonly use pre-filter particulate vessels?

They are widely used in fuel distribution, power generation, marine operations, aviation fuel handling, chemical processing, and industrial maintenance projects where bulk solids must be removed to protect downstream equipment.

Can these vessels handle contaminated fuel with water present?

Pre-filter vessels remove particulate only — not free or emulsified water. However, they are commonly paired with coalescer or water-absorption stages in systems where both solids and water need to be addressed.

How do I know if my system needs a vertical or horizontal vessel design?

Vertical vessels are preferred when footprint space is limited or when gravity-assisted draining is beneficial. Horizontal vessels are chosen for high-flow operations or when ease of element/basket access is a priority. The correct choice depends on your available space, flow requirements, and service personnel needs.

Want the most up to date information from PFP?

Sign up for our E-mail newsletter!

Want the most up to date information from PFP?

Sign up for our E-mail newsletter!