coalescer-separator filter vessels

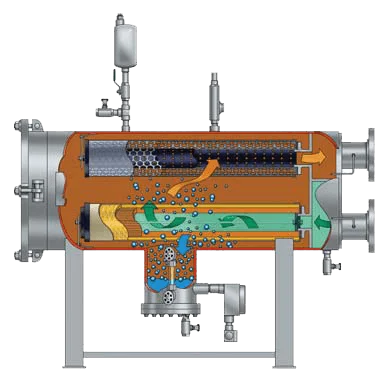

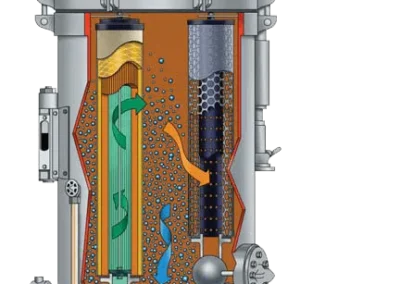

Two-stage coalescer-separator filter vessels are the primary defense against fuel contamination by water and dirt. The coalescer separator housings contain both first-stage coalescer and second-stage separator cartridges with no internal moving parts. They are designed to meet commercial and military Energy Institute (EI) test specifications.

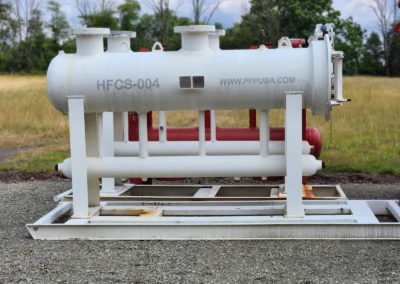

Our two-stage coalescer separators will continuously remove solids and water contaminants from aviation fuels. Vertical and horizontal housing designs are available with a wide selection of coalescer and separator cartridges to meet specific applications. All are built to ASME Code, Section VIII, with many standard and optional accessories and connections available to facilitate piping and installation requirements.

Looking for a temporary system, check out our Emergency Rental Page to see a list of our Coalescer-Separator Filter Vessels available for short and long term rentals.

Have questions? Reach out to us – we’re here to help.

Materials of Construction

Carbon Steel

- Interior – Epoxy Coated

- Exterior – Prime Coated

Accessories & On-Site Support

We can supply you with the temporary Cargo Hose, Gate Valves, Tees, Elbows, Pump, Portable Containment, and many more to provide you a complete turnkey set up. We have service crews available to set up, monitor, and breakdown the temporary systems as well.

- Vertical & horizontal configurations available

- Designed to filter solids and separate water from fuels

- Easy service and reduced maintenance costs

- Qualified to 5th Edition of EI 1581, Category C, Type S

- EI 1596 Design & Construction

- Built to ASME Code, Section VIII, stamped and certified or “CE” marked

- Automatic air eliminator

- Differential pressure gauge

- Pressure relief valve

- Sampling probe

- Cartridge hoist assembly

- Working platform, ladder and handrails on 42″ (1067 mm) OD and larger housings

- Removable bundle design

Frequently Asked Questions

What types of contaminants do coalescer-separator vessels remove?

These vessels are designed to remove both solid particulates and free water from fuels or light oils. The coalescer stage captures solids and forms large water droplets, while the separator stage removes the coalesced water before the fuel exits the vessel.

How often should coalescer and separator elements be replaced?

Element life depends on fuel quality, solids loading, and water content. Coalescer elements typically require more frequent replacement than separator elements. Routine outlet testing and differential pressure readings are the best indicators of when a changeout is required.

Can coalescer-separator vessels handle emulsified water?

Yes, but performance depends on the fuel’s surfactant load. High surfactant levels can reduce separation efficiency, which is why clay treaters or pre-filters are often placed upstream to restore proper coalescing performance.

What information is needed to size a coalescer-separator vessel correctly?

Key information includes flow rate, fuel type, allowable water content, expected solids load, temperature, and whether the application is permanent or temporary. This determines the proper vessel diameter, element count, and flow configuration.

Are coalescer-separator vessels suitable for aviation fuel or only industrial fuels?

They are widely used for both. These vessels are standard equipment in aviation fuel handling, pipeline terminals, military operations, and industrial fuel purification systems where water removal and particulate control are critical.

Want the most up to date information from PFP?

Sign up for our E-mail newsletter!

Want the most up to date information from PFP?

Sign up for our E-mail newsletter!