clay treater vessels

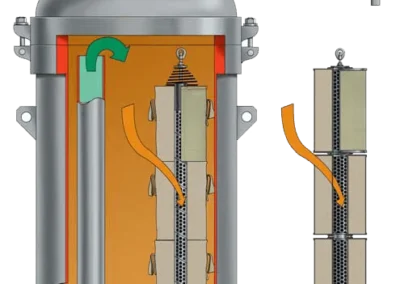

Clay Treaters are used in multiproduct pipeline installations, and wherever surfactant laden or discolored fuel is a problem. They can be configured to accept bags or canisters.

Clay treaters will continuously adsorb surfactants, color and additives from jet fuel when used with Facet replaceable clay elements. Housings are designed for easy servicing and low maintenance. All are built to ASME Code, Section VIII. Standard and optional accessories and connections are available to facilitate piping and installation requirements.

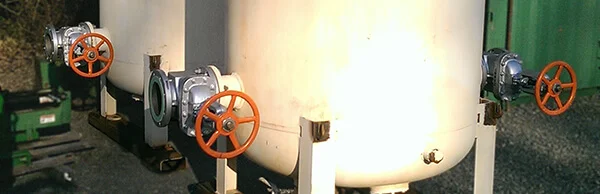

Looking for a temporary system, check out our Emergency Rental Page to see a list of our Clay Treaters available for short and long term rentals.

Materials of Construction

Carbon Steel

- Interior – Epoxy Coated

- Exterior – Prime Coated

Have questions? Reach out to us – we’re here to help!

Accessories & On-Site Support

We can supply you with the temporary Cargo Hose, Gate Valves, Tees, Elbows, Pump, Portable Containment, and many more to provide you a complete turnkey set up. We have service crews available to set up, monitor, and breakdown the temporary systems as well.

- Welded carbon steel construction

- ASME Code, Section VIII construction, stamped and certified

- Design pressure: 150 psi @ 250°F

- Inlet and outlet permanently marked

- Interior: Epoxy coated

- Exterior: Prime coated

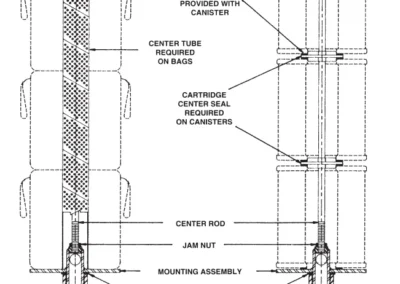

- Removable cartridge mounting post

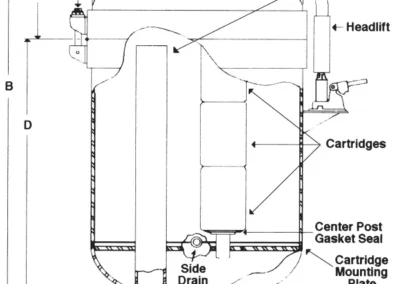

- Swing bolt closure

- Buna-N closure gasket

- Hydraulic headlift

- Automatic air eliminator

- Differential pressure gauge

- Pressure relief valve

- Sampling probe

- Cartridge hoist assembly

- Working platform, ladder and handrails on 42″ (1067 mm) OD and larger housings

- Removable bundle design

Frequently Asked Questions

What contaminants do clay treater vessels typically remove?

Clay treaters are most effective at removing surfactants, soaps, color bodies, additives, and trace hydrocarbons that cause haze or discoloration. They are commonly used when product clarity is required or when fuel quality specs must be restored.

How often do clay cartridges need to be changed out?

Changeout intervals depend on contaminant loading and flow rate. In heavy surfactant or additive contamination scenarios, cartridges may require more frequent replacement. Routine operations typically have longer service intervals based on outlet quality testing.

Can clay treater vessels be used on aviation fuels like Jet A or Jet A-1?

Yes. Clay treaters are widely used in aviation fuel filtration systems to remove surfactants and additives that can interfere with downstream coalescer performance, ensuring compliance with fuel clarity and conductivity requirements.

What information is needed to size the correct clay treater vessel?

To size the proper unit, providers usually need: fluid type, flow rate, inlet contaminant levels, expected outlet clarity specs, temperature, and whether the application is temporary or permanent.

Can clay treaters be integrated into multi-stage filtration setups?

Absolutely. Clay treaters are often placed upstream of particulate or coalescing filters to protect cartridges and improve water-separation performance. They are a standard component in multi-stage fuel purification designs.

Want the most up to date information from PFP?

Sign up for our E-mail newsletter!

Want the most up to date information from PFP?

Sign up for our E-mail newsletter!